Photos courtesy of Corporate Contractors Inc.

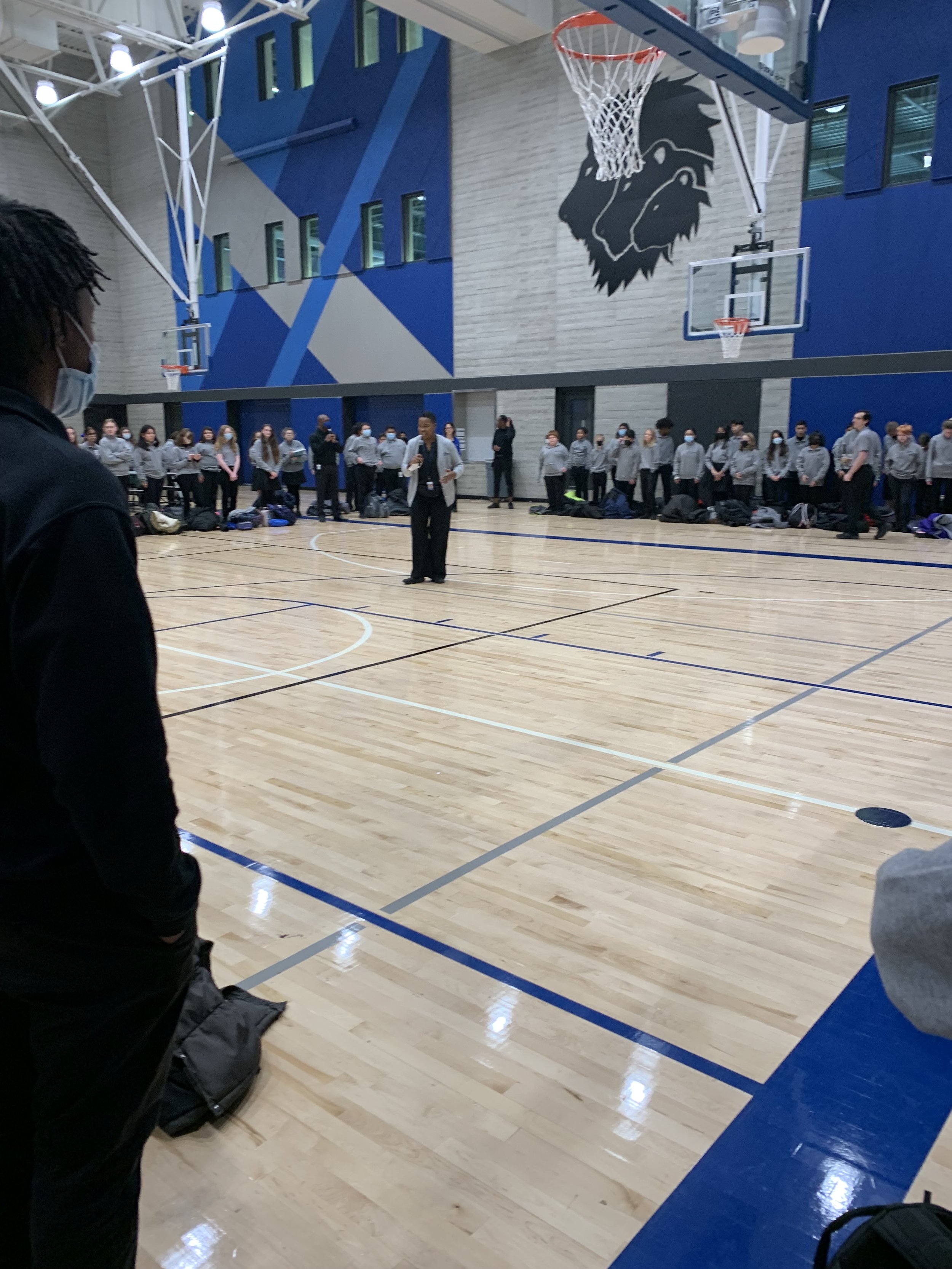

Built from the ground up with input from the community – including parents, community, civic leaders, and, most importantly, scholars – access and equity drives The Lincoln Academy as an innovative, high quality public school option focused on scholar success, according to the website of the brand new school which will end its first school year on June 14.

Chief Education Officer of The Lincoln Academy Kristi Cole said the school had a fantastic first year focused on career exploration, academic rigor, and character development.

“The best part of the school year for me I think and for the school is the scholars’ energy and excitement they bring to learning,” Cole said. “Whether I’m upstairs in an engineering lab and they are learning to program a CNC machine, or learning to create a robot, or the art club learning how to make stained glass – just watching them be excited to be learning about whatever it is they are doing. That’s the best part - when you see that joy of learning and excitement about being at school.”

To get the school up and running for the 2021-22 school year, Corporate Contractors Inc., the general contractor on the project, had to take off at a run.

“We enjoy being part of projects that are bigger than ourselves,” said CCI Project Manager Aaron Combs. “It’s really going to transform lives and it’s going to pick up where maybe the school districts are failing. It’s really going to transform scholars’ lives. It’s going to give them a future beyond anything they ever saw possible.”

The school was actually started based on community input and a desire for another option for a public school. Over the course of many meetings with parents and the community to determine what needs the school could meet, The Lincoln Academy, its pillars, and curriculum were created.

“Our goal is to be able to help build strong character in our scholars, strong academics, and a willingness to support their community,” Cole said.

The 2021-22 school year included about 400 scholars in grades K4-2nd and 6th-9th, with a plan to add one grade level per year until the school reaches 700 scholars. Every scholar has an individualized learning plan that focuses on what they want to be and how they are going to get there.

Precast concrete wall panels were used to create the gymnasium at the center of the building. A wood grain form liner with reveals and smooth form finish on the upper portions were used to provide a pleasing aesthetic finish. The wall panels will maintain their look and durability for generations to come.

“One of the most important things for us is to be involved in our community,” said Jeremy Olivotti, Mid-States Concrete’s Vice President of Preconstruction. “An opportunity to be part of a project where people work, learn, and play gets us very excited.”

Combs noted one of the major challenges of this project was its tight timeline. The project was completed in just 11 months. Because precast bears the floors and the ceilings, it provided a quick solution to get the building up as quickly as possible. The form liner helped elevate the area from just a supporting structure to a focal piece.

“This project was installed on schedule for CCI,” said Mid-States Concrete Project Manager Brad McCaslin. “We mobilized early to set what wall panels had been produced for their groundbreaking ceremony. It was important that we be there for the groundbreaking ceremony to show progress. Up until that time, the jobsite was nothing more than a hole in the ground. CCI has been a great partner with us and we wanted to do everything we could to get there as soon as possible.”

In addition to the quick installation helping keep the project on schedule, use of precast concrete also provided the benefit of offering clean construction.

“You walk in to a clean site, you put the walls up, and you walk out,” Combs said. “It’s a simple installation process; it’s clean; it’s not something that’s going to mess up a site. It was a two-day install and at the end of the day, it was the perfect application.”

Combs added the safety aspect of Mid-States Concrete was another benefit as precast contributed to a safe job site and that isn’t something you can put a dollar figure on.

In the upcoming school year, The Lincoln Academy will focus on continuing to fine-tune its systems and individualized support for the school’s scholars to make sure they are reaching their goals. The school will also focus on continuing to build its career exploration pathways, now that the scholars have expressed their interests and goals.

“Every decision we make is about children first,” Cole said.

Precast:

38 Wall Panels (18,800 square feet)

Wood grain formliner inside the gymnasium

Partners:

GC: Corporate Contractors Inc.

Architect: Eppstein Uhen Architects

Further Reading:

The Lincoln Academy

Photos courtesy of The Lincoln Academy.