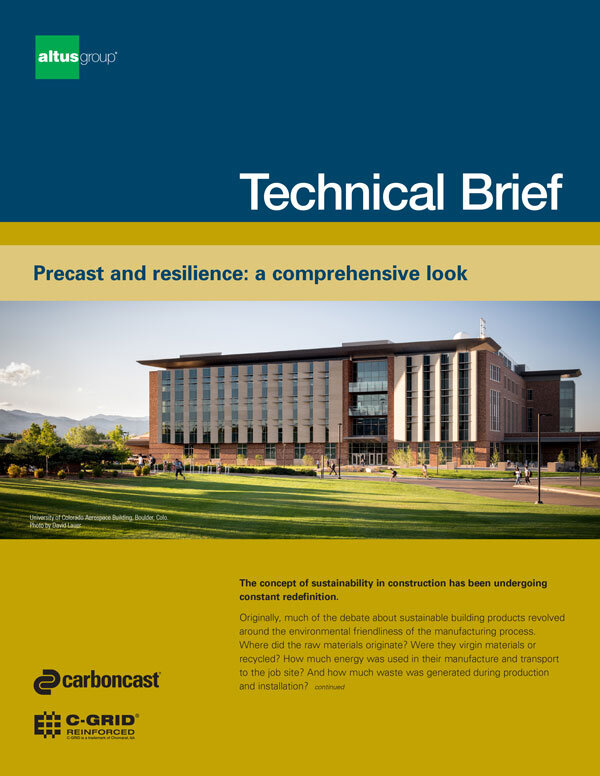

The concept of sustainability in construction has been undergoing constant redefinition. Originally, much of the debate about sustainable building products revolved around the environmental friendliness of the manufacturing process. Where did the raw materials originate? Were they virgin materials or recycled? How much energy was used in their manufacture and transport to the job site? And how much waste was generated during production and installation?

The concept quickly evolved to encompass how the product or system performed to reduce energy usage in a building or reduce the building’s operating carbon footprint. Would the products lower energy draw and use? Utilize less water? Enhance daylighting? Reduce VOCs, improve indoor air quality and enhance worker productivity?

The added philosophy of “resilience” has now moved to the forefront. Not only must a building product be manufactured in a sustainable manner and provide environmental benefits once a building is commissioned, it must deliver those benefits over an extended period of time - with the impact of maintenance factored in.

CarbonCast wall panels are a sustainable and resilient choice.

Embodied energy

Transport to the job site

Erection

Fire Resistance

Energy savings, thermal performance, moisture performance

Durability

Earthquake Resistance

Blast Resistance

Learn more in this Technical Brief from AltusGroup >>

Mid-States Concrete Industries is a proud member of AltusGroup, an international collaboration of precst concrete companies dedicated to speeding and perfecting the development of precast technologies that improve the built environment. AltusGroup members work together to bring advanced technology to market, then compete against one another for work.

At Mid-States Concrete Industries, your project is a big deal. That’s why our team ensures that each project not only begins successfully but is completed successfully as well. Your project is unique. Our team will ask questions and listen to your objectives and goals so we can apply the latest design and engineering techniques to your projects, adhering to the strictest safety standards in the industry. As a Precast/Prestressed Concrete Institute Certified Plant and Erector, our precast concrete components are manufactured and installed according to stringent industry standards.

Have questions regarding CarbonCast Wall Panels or precast concrete in general? Our team is happy to help! Contact our sales team at sales@msprecast.com.