Maine West High School: Des Plaines, Ill.

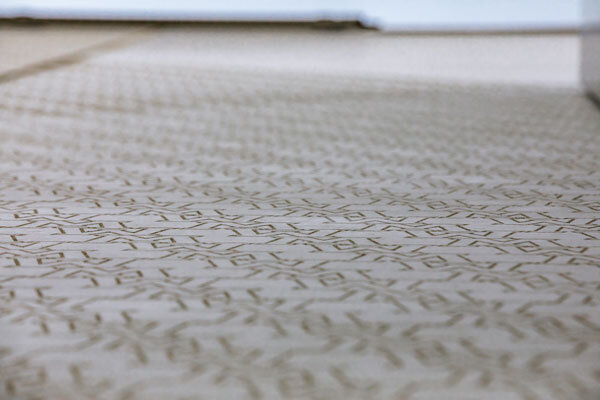

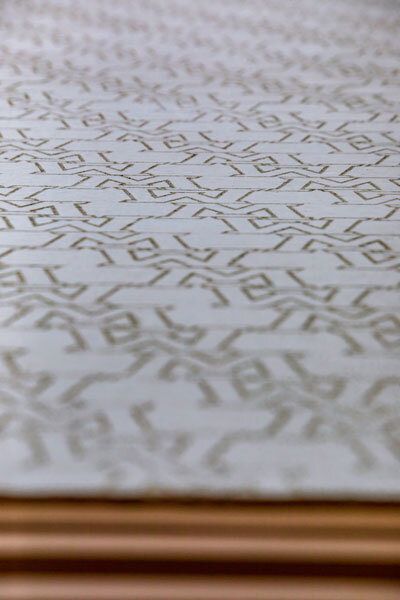

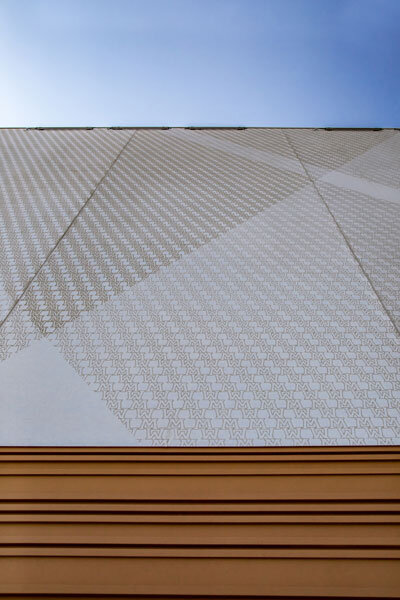

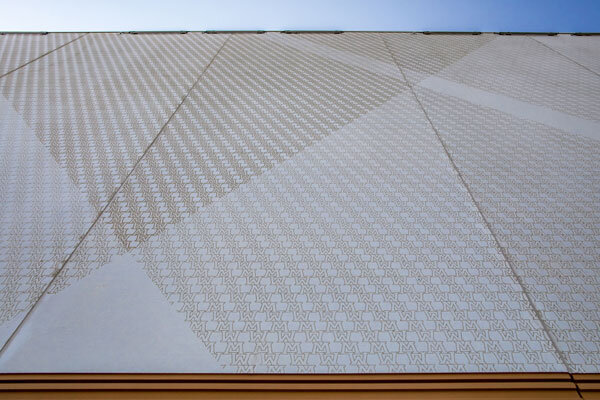

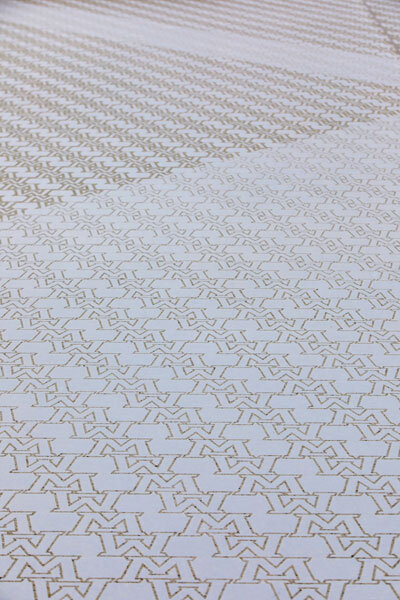

When Wight and Company first contacted Mid-States about the Maine West Field House addition, the project was planned as a precast structure with a metal cladding of athletic figures attached to the wall panels. Representatives of the architectural firm were looking for the ability to add a design directly into the precast using the Graphic Concrete process. The designers knew the image had to blend in with the rest of the precast building and the existing structure. In addition to utilizing Graphic Concrete, the project also uses form liners, sandblast finishes, and Nawkaw stain. The Graphic Concrete is the school’s name, Maine West, stretched across the entire north and south sides of the building using multiple colors.

”It’s been a long time coming,” said Athletic Director Jarett Kirshner. “In our 1968 yearbook, the construction of the field house is mentioned and a photo of the site for construction of the facility was printed… As an athletic administrator, I love the beauty, modern look and equipment, and the fact that all of the indoor facilities are now on the same side of campus.”

The field house includes basketball courts, track and field space, volleyball courts, batting cages, and locker rooms. All 2,000+ students will use the facility at some point.

”The competition courts are also much more appropriate for high school competitions than the small gyms we have been using,” Kirschner said.

In addition to the physical education department, most of the school’s sports will use the facility for training and/or competition including: Cheerleading, Wrestling, Boys and Girls Volleyball, Boys and Girls Track, Badminton, Boys and Girls Basketball, Softball, Baseball, Football, and Boys and Girls Soccer. With the use of dividers, multiple sports can train at the same time, and the facility will also be used for student activities like dances, meetings, and graduation practice.

”The field house has already added so much for our athletes, coaches, and programs,” Kirshner added. “The proximity of the facilities to each other make it easier for people to navigate to the proper venue, it has increased security, and the coaches and athletes are closer to the Athletic Training Room and Fitness Center.”

The school district looks forward to hosting the first indoor track meet in the history of the school, and other large events.

”For our physical education classes, this has instantly become an incredible instructional space,” Kirshner said. “Multiple classes can be engaged in activities in a safe and bright environment, with some great equipment, outstanding practice/competition courts, and a beautiful track.”

Kirshner said the feedback has been outstanding and very positive from the students, coaches, administration, staff, community, officials, opponents, and alumni. He added the exterior of the field house has been a hit.

”The design is amazing and the integration of the little MWs in the design is almost breathtaking to those who first see it,” Kirshner said.

Precast Elements:

110 Wall Panels (40,103 square feet)

Project Partners:

General Contractor: Pepper Construction

Architect: Wight & Company

EOR: Wight and Company

Beloit Memorial High School Natatorium: Beloit, Wisc.

The Beloit Memorial High School pool is an exciting addition to the school and the community. Hollowcore plank was used for the mezzanine and low roof areas and wall panels were used for the exterior structure. The panels have large, punched openings that provide a great view of the river.

The grand opening in August 2013 celebrated the new Beloit Memorial High School natatorium, which was designed to meet the growing demand for swim instruction and swim programs for both high school and middle school students in Beloit.

”We call our pool the BTIDE Home,” said Head Swim Coach Richard Vogel. “Our kids consider the natatorium home… Our kids take a lot of pride in our facility. We are proud to have a first-class facility like this in Beloit.”

During the school year, the high school physical education department uses the pool. It is also used for lifeguard classes, outdoor education classes, Special Olympics swim team, and second and fourth grade swimming lessons for elementary school physical education. Overall, the schools use the pool five-to-six-hours each day and the USA Swim team uses the pool for two-to-three hours each day.

”Learning to swim is a life skill that can save your life,” Vogel said. “We have a river running right next to our school.”

The school district hosts roughly 30 swim meets per year, including the Big 8 Conference Meet for both the boys and girls swim teams, the WIAA Sectionals, Rock County Championships, middle school conference meets, and USA swimming regional meets.

”The Boys High School Swim Team has never lost the Rock County Championship in our pool - five years in a row,” Vogel said.

The pool brings a lot of people from outside the community due to its seating capacity and speed of the pool. According to Vogel, swimmers want to swim in their pool because it is so fast. Because the natatorium is almost 25,000 square feet, it allows the facility to offer high quality training with a lot of kids at one time. The balcony is set up as a strength training facility but is opened for spectators for big meets. The pool features eight wide lanes, which allows more swimmers to use the pool at one time, while still having space for diving practice.

Some of Vogel’s favorite memories within the space in recent years include winning five straight Rock County Championships, the Girls Swim Team winning the National Swimming Coaches Association National Academic Award in 2015, taking senior pictures in the pool, hosting major swim meets, and watching future American Record Holder Beata Nelson (of Verona High School) set five pool records in their facility.

Precast Elements:

52 Wall Panels (12,662 square feet)

8,004 square feet of Hollowcore

Project Partners:

GC: Corporate Contractors, Inc.

Architect: Bray Architects

EOR: Ambrose Engineering